Ok. I got a basic understanding on the PID temp controller

I have set up the following ramp schedule:

| STEP | CO= SET POINT | T= MINUTES | HOURS |

| 1 | 90 | 60 | 1 |

| 2 | 91 | 120 | 2 |

| 3 | 95 | 240 | 4 |

| 4 | 98 | 480 | 8 |

| 5 | 99 | 480 | 8 |

| 6 | 100 | 480 | 8 |

| 7 | 100 | 480 | 8 |

| 8 | 101 | 480 | 8 |

| 9 | 110 | 240 | 4 |

| 10 | 115 | 240 | 4 |

| 11 | 120 | 240 | 4 |

| 12 | 120 | 480 | 8 |

| 13 | 120 | 480 | 8 |

| 14 | 135 | 480 | 8 |

| 15 | 135 | 960 | 16 |

| 16 | 149 | 960 | 16 |

| 17 | 149 | 480 | 8 |

| 18 | 165 | 480 | 8 |

| 19 | 165 | 480 | 8 |

| 20 | 165 | 0 | 0

|

This gives me the sought after and reccomended hours for curing. I havent really looked if the right hours are devoted to each phase tho so this chart is for sure not complete and will be changed. I am going to watch the soak phases to make sure they are set up and the PID doesn't skip them............

Submitting it now just shows that my PID is working as it is told finally.

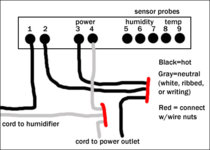

ALSO I have the new humidifier element installed. It is working somewhat slower than I had thought and makes me rethink just how hard that lil crock pot is actually working !

It brought humidity from 55% to 78% in 20 minutes.

Is taking longer than I am thinking as I can actually see the water vapor rising as compared to the hot plate.

I am thinking that I may have to tape up the holes in my air flow plate so that more air comes to the bottom to carry it upwards. Is possible that it is now being held down somewhat away from sensor.

I think the ultrasonic humidifier is a good idea tho especially in my case where hot plate caused to much temp to get to the desired RH for yellowing.

Also my little fan may be inadaquate for good circulation tho it seems to spread heat good without any leaves in it so far.