leverhead

Well-Known Member

For me, sewing is the worst part of making bud bags. Handling Agribon 15 is hard enough for cutting, sewing it was not something that I was looking forward to. Agribon is made from spun Polypropylene, it gets soft and sticky at clothes iron temperatures. That makes it a good candidate for heat bonding/welding the seams. The trick is to make it stick to itself, not everything else it comes into contact with. Parchment paper from the shelf right next to the wax paper at the grocery store works just fine as a non stick surface and is relatively inexpensive.

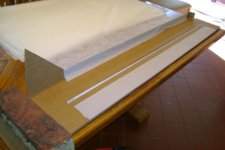

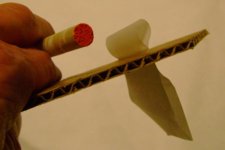

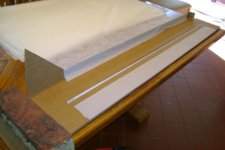

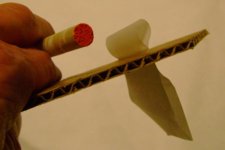

The fixture I made to hold everything snugly together in position and keep the Agribon covered with a non stick surface, is pretty easy to make. It's basically three layers thick of corrugated cardboard. A base layer 8"(20cm) X 48"(122cm) long, corrugations running the long way. The middle layer is the same as the first with a 40"(102cm) slit down the center line, the long way. A 5/16"(8mm) X 39 3/8"(1m) long wooden dowel is attached to the top surface through this slit with parchment paper the length of the dowel.

The top layer is cut 9 1/2"(24cm) X 48"(122cm) long, similar to the other two layers, the extra 1 1/2"(4cm) of width is partially cut from the bottom and bent up to form a stiffening rib running the long way. There is a window 1/2"(12.7mm) wide X 40"(102cm) long in this layer that should center over the slit in the middle layer.

I've allowed 2"(5cm) at one end of the assembly as a hinge, so both the window and slit start at 5" from the hinge end and finish 3" from the far end. The bottom surface of the top layer is covered with parchment with just enough extra to cover the dowel snugly. The parchment is stapled in place, glue doesn't stick to it.

The fixture I made to hold everything snugly together in position and keep the Agribon covered with a non stick surface, is pretty easy to make. It's basically three layers thick of corrugated cardboard. A base layer 8"(20cm) X 48"(122cm) long, corrugations running the long way. The middle layer is the same as the first with a 40"(102cm) slit down the center line, the long way. A 5/16"(8mm) X 39 3/8"(1m) long wooden dowel is attached to the top surface through this slit with parchment paper the length of the dowel.

The top layer is cut 9 1/2"(24cm) X 48"(122cm) long, similar to the other two layers, the extra 1 1/2"(4cm) of width is partially cut from the bottom and bent up to form a stiffening rib running the long way. There is a window 1/2"(12.7mm) wide X 40"(102cm) long in this layer that should center over the slit in the middle layer.

I've allowed 2"(5cm) at one end of the assembly as a hinge, so both the window and slit start at 5" from the hinge end and finish 3" from the far end. The bottom surface of the top layer is covered with parchment with just enough extra to cover the dowel snugly. The parchment is stapled in place, glue doesn't stick to it.