The Theory

PART 1 of 2

My notion of what happens when tobacco hands are piled into a large, traditional pilon is that only the middle of the pile ferments. This is why the pilon must be taken apart and rebuilt a number of times, switching the inner tobacco hands to the outside, and the outer hands to the inside. My thought is that most of the pile is simply serving as insulation. The pressure from the height of the pile really generates very low psi--certainly less that 1 psi, but does serve to gently compress the krinckled leaf into close contact.

My hope was that by providing a well insulated box in which to gently compress a small number of hands of color-cured tobacco might allow its enzymatic oxidation to generate the same heat as in a pilon. This would be a box without a separate heat source, and only a compost thermometer to determine what was happening within.

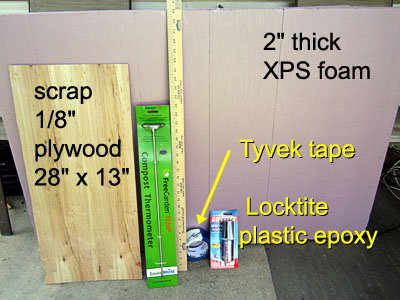

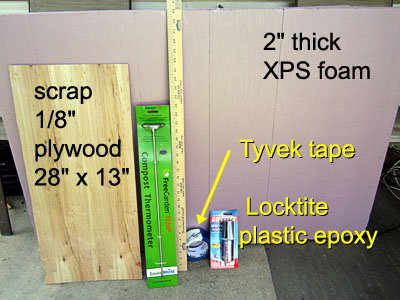

I gathered some components for the project:

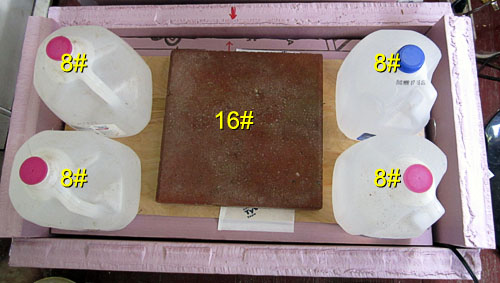

My plan was to use Plastic Epoxy (either LocTite or JB Weld) to glue together a box made from 2" Foamular extruded polystyrene (XPS) foam. The outer seams would be sealed with Tyvek tape. The top panel would float inside the box, allowing it to be weighted with 3 or 4 one-gallon water jugs. A scrap of 1/8" plywood would help distribute the weight of the jugs evenly across the top. A 19" analog compost thermometer would rest inside the box, at the bottom, and its dial would extend outside the box.

My expectation was that within 48 hours of pressing high-case tobacco hands into the box, and covering it with a sheet of thick plastic for vapor control, the temperature would begin to rise (hopefully to at least 110ºF).

Demonstration of the strength of plastic epoxy bond on XPS foam.

Bob

PART 1 of 2

My notion of what happens when tobacco hands are piled into a large, traditional pilon is that only the middle of the pile ferments. This is why the pilon must be taken apart and rebuilt a number of times, switching the inner tobacco hands to the outside, and the outer hands to the inside. My thought is that most of the pile is simply serving as insulation. The pressure from the height of the pile really generates very low psi--certainly less that 1 psi, but does serve to gently compress the krinckled leaf into close contact.

My hope was that by providing a well insulated box in which to gently compress a small number of hands of color-cured tobacco might allow its enzymatic oxidation to generate the same heat as in a pilon. This would be a box without a separate heat source, and only a compost thermometer to determine what was happening within.

I gathered some components for the project:

My plan was to use Plastic Epoxy (either LocTite or JB Weld) to glue together a box made from 2" Foamular extruded polystyrene (XPS) foam. The outer seams would be sealed with Tyvek tape. The top panel would float inside the box, allowing it to be weighted with 3 or 4 one-gallon water jugs. A scrap of 1/8" plywood would help distribute the weight of the jugs evenly across the top. A 19" analog compost thermometer would rest inside the box, at the bottom, and its dial would extend outside the box.

My expectation was that within 48 hours of pressing high-case tobacco hands into the box, and covering it with a sheet of thick plastic for vapor control, the temperature would begin to rise (hopefully to at least 110ºF).

Demonstration of the strength of plastic epoxy bond on XPS foam.

Bob