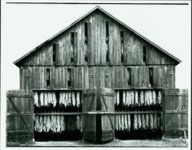

I’m starting a small farm and want to build a small/medium sized barn for curing burley. I’ve seen how the bulk farmers harvest and hang on wooden stakes whole plants by the stalk. And they seem to have multiple tiers of plants hanging under the top row located at the ceiling of the barn. This method seems simple enough but if there’s anyone who has build experience in this and or alternative method for hanging 2000 plants /4000 plants so just a small farm but enough to supply the whole family and sell the rest.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Advice for building a burley barn

- Thread starter Libsk8r1

- Start date

- Status

- Not open for further replies.

Some info on curing barns:

Several different pdf’s on racks, barns, etc.

Interesting, with some clues:

en.wikipedia.org

en.wikipedia.org

Several different pdf’s on racks, barns, etc.

Interesting, with some clues:

Tobacco barn - Wikipedia

More cool barns and old images

130 TOBACCO BARNS ideas | old barns, barn, country barns

May 25, 2019 - Explore Bobbie's board "TOBACCO BARNS", followed by 1,061 people on Pinterest. See more ideas about old barns, barn, country barns.

Last edited:

Burleyfarmer

Member

The cheapest method by far is outdoor scaffolding for burley curing. It basically consists of a row of poles with 3 boards running along the top portion 2 on one side and one on the other side of the poles. There should be about a 1 inch gap for the tobacco stick to be stuck into the scaffold. I know that is not the best description, but there is a more detailed description at http://www2.ca.uky.edu/agcomm/pubs/id/id116/id116.pdf

You can cover it with plastic for curing, or make a roof over it. Around here alot of folks get scrap tin from the scrapyard and make a cheap roof over the top. This system will hang the most sticks of tobacco for the least amount of construction material and by far is the fastest system for hanging tobacco especially if you build it in the edge of the tobacco field. Barns require climbing, and a sort of acrobatics in order to hang tobacco in them. Not to mention that hanging in a 3 or 4 tier barn is a real pain if you plan on doing the work by yourself, because you will have to hang a tier and then climb up and move it up another tier, until you get it in the top. You cannot hang tobacco as close on the poles in a barn as you can on a scaffold either. It will houseburn if too close on the poles. At the same rate, burley will not cure properly if you do not have a full barn, or the barn hung at a proper capacity. What makes the scaffold good, you can hang most tobacco 5 stalks to a stick and the sticks about 4 inches apart, in the scaffold, if field wilted good. AT least that is the capacity that my climate seems to uphold best for curing. It will be different in every area, and climate. It can also be hung closer together in a sunny and dry spot, than in a damp or slightly shaded area.

If you have the time and material, a barn is better for multipurposing, and you will have less sticks to fall in windy weather. Sometimes you will have some sticks of lighter weighted tobacco blow out of the scaffold, more so than in a barn- though I have had whole rungs of tobacco blown down in real windy weather even in a barn. Everything has its tradeoff. If you are sure you will grow burley for a long period of time like 20 years or something, I would go with building a curing barn. If this is more experimental or you are not sure you will grow for a long period of time- Scaffolding is best. I have seen tobacco barns 7 tiers high- you definitely DO NOT want to build one of those- trust me. Nothing but Labor, and when you quit burley- wasted/ useless barn space. In small amounts 1 tier is definitely the way to go.

By the way 2000-4000 plants will be a lot of tobacco for one family. You are looking at somewhere between .25 and .75 of an acre of tobacco based on spacing in the field, and with a good yield on that amount acreage anywhere from 600lb for .25 acre (average yeild)- 2400 lb for .75 acre (higher end yield)of tobacco. I am told that current processing at a Manufacturer would put that at 6 cartons of cigarettes to the lb of tobacco. 3600-14,400 cartons? Home processing will be much less, but still a lot.

I joke every year when I plant my tobacco, that If the markets are bad I will be chewing alot this winter.

Hope this info is of some help. I've hung alot of tobacco in my time- you will probably be very pleased with a scaffold. I wish every stick I ever hung could have been put in one, and have been properly field wilted first. I bet my left shoulder would not keep me awake at night.

You can cover it with plastic for curing, or make a roof over it. Around here alot of folks get scrap tin from the scrapyard and make a cheap roof over the top. This system will hang the most sticks of tobacco for the least amount of construction material and by far is the fastest system for hanging tobacco especially if you build it in the edge of the tobacco field. Barns require climbing, and a sort of acrobatics in order to hang tobacco in them. Not to mention that hanging in a 3 or 4 tier barn is a real pain if you plan on doing the work by yourself, because you will have to hang a tier and then climb up and move it up another tier, until you get it in the top. You cannot hang tobacco as close on the poles in a barn as you can on a scaffold either. It will houseburn if too close on the poles. At the same rate, burley will not cure properly if you do not have a full barn, or the barn hung at a proper capacity. What makes the scaffold good, you can hang most tobacco 5 stalks to a stick and the sticks about 4 inches apart, in the scaffold, if field wilted good. AT least that is the capacity that my climate seems to uphold best for curing. It will be different in every area, and climate. It can also be hung closer together in a sunny and dry spot, than in a damp or slightly shaded area.

If you have the time and material, a barn is better for multipurposing, and you will have less sticks to fall in windy weather. Sometimes you will have some sticks of lighter weighted tobacco blow out of the scaffold, more so than in a barn- though I have had whole rungs of tobacco blown down in real windy weather even in a barn. Everything has its tradeoff. If you are sure you will grow burley for a long period of time like 20 years or something, I would go with building a curing barn. If this is more experimental or you are not sure you will grow for a long period of time- Scaffolding is best. I have seen tobacco barns 7 tiers high- you definitely DO NOT want to build one of those- trust me. Nothing but Labor, and when you quit burley- wasted/ useless barn space. In small amounts 1 tier is definitely the way to go.

By the way 2000-4000 plants will be a lot of tobacco for one family. You are looking at somewhere between .25 and .75 of an acre of tobacco based on spacing in the field, and with a good yield on that amount acreage anywhere from 600lb for .25 acre (average yeild)- 2400 lb for .75 acre (higher end yield)of tobacco. I am told that current processing at a Manufacturer would put that at 6 cartons of cigarettes to the lb of tobacco. 3600-14,400 cartons? Home processing will be much less, but still a lot.

I joke every year when I plant my tobacco, that If the markets are bad I will be chewing alot this winter.

Hope this info is of some help. I've hung alot of tobacco in my time- you will probably be very pleased with a scaffold. I wish every stick I ever hung could have been put in one, and have been properly field wilted first. I bet my left shoulder would not keep me awake at night.

Excellent reference, @Burleyfarmer , and good advice. Most of the growers on the forum, including myself, grow much smaller crops, and have no experience with the practicalities of grows that approach an acre or larger.

Bob

Bob

Homegrowngoodnes

Well-Known Member

I originally planned on planting about 2400 plants though im leaning towards doing much less and planting a second crop when the first one is harvested as we have about 225 frost free days here to grow. That would spread out labor times for me and the first crop should be cured by the time the second crop is harvested. Im still researching how i will air cure my crop. I will likely be priming my plants rather than hanging whole stalks. Im taking rh readings in various places in my house. The hygrometer is currently in my attic. Tomorrow afternoon i will climb up there to check it out. Humidity is really high in florida so im trying to get a feel for it. I fear the mold!

Compare your daytime humidity with your night time humidity. My humidity swings where I live. It can be high at night and low during the day. (I watch three day blocks of time and shoot for the average) During those swings I open and close the doors depending on whether I am trying to trap higher humidity inside while the humidity lowers outside, or I try to keep lower humidity inside while keeping the higher humidity outside such as during a rainy spell. During periods of lower humidity, I push the leaf closer together so that they “share” humidity and dry out more slowly, or if it is high I will spread the leaf further apart and turn on the shop fans to increase air circulation to help prevent mold or rot. When the leaf is greenish and humidity is high, rot is more of a problem. I have to watch the hygrometer and the upcoming weather and make allowances. You also will develop a feel for the leaf. If your humidity stays consistently high, you may need a dehumidifier. I use them in my basement where I store my tobacco. If you hit about a three day average of low humidity you can suspend towels from buckets of water to act as a wick and raise humidity, or wet the floor if the floor is dirt. I’ve done that with concrete but it dries out really fast, although it will temporarily raise the humidity short term and just keep doing it until you’re over the hump. I don’t like misting the leaf, but have done that when running out of options. If you are growing flue cure varieties or orientals I recommend sun curing or a flue cure chamber. A flue cure chamber takes the fight out of your climate but burley doesn’t flue cure well. Keep us updated on your readings.I originally planned on planting about 2400 plants though im leaning towards doing much less and planting a second crop when the first one is harvested as we have about 225 frost free days here to grow. That would spread out labor times for me and the first crop should be cured by the time the second crop is harvested. Im still researching how i will air cure my crop. I will likely be priming my plants rather than hanging whole stalks. Im taking rh readings in various places in my house. The hygrometer is currently in my attic. Tomorrow afternoon i will climb up there to check it out. Humidity is really high in florida so im trying to get a feel for it. I fear the mold!

Some curing chambers:

China Voodoo's Invertebrate Kiln

I'm using a temperature controller. Temperature is produced by two 40W incandescent bulbs which hang inside an aluminum tube, with forced air provided full time by a 110V fan purchased at princess auto. The tube is bent so it blows air from the bottom to the top. Tobacco is in...

Deluxestogie's Endoskeletal Wood Tobacco Kiln / Flue-cure chamber

PART 1 of 4 Endoskeleton. The foam board goes on the outside. Caveat The wood-built kiln discussed here has several advantages over using a dead, upright freezer for a kiln, but will require more work to complete, and will certainly cost more. it weighs significantly less it can be sized to...

Knuckleheads Wooden Box Kiln Build

I've been meaning to build a kiln for the past two seasons but have just gotten off my sorry ass and decided to do something about it. (Bob's thread kicked off my thinking seriously about it) First, let me say that the cheapest kiln build is one from a free freezer, as the box itself is the most...

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 2K

-

About Us

This forum is dedicated to promoting the American tobacco farmer and tobacco home growers across the globe. Whether you grow by the acre, in your backyard, or in pots, you should find valuable and accurate information here.We discuss any variety of tobacco, as well as numerous approaches to growing, harvesting, curing, and finishing your crop. Our members will attempt to provide experience-based answers to your questions.

-

Buy raw tobacco from our Sponsor - WLT