Making a Crumble-Cake

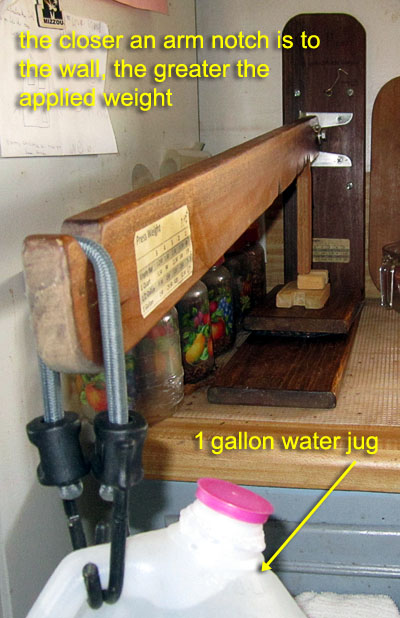

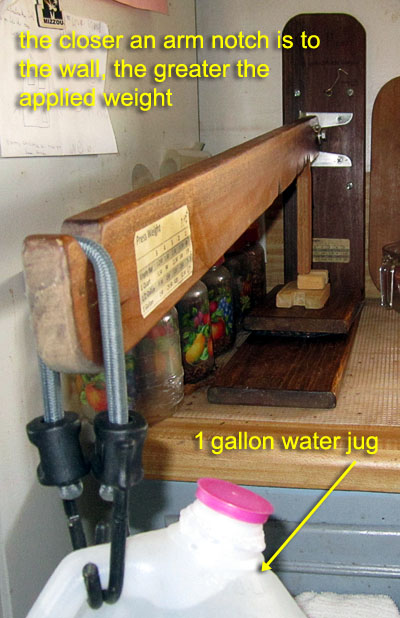

By placing a pipe blend into a (in this case, quart-size) freezer Ziploc bag, it can be pressed for general melding, or pressed into a crumble-cake between two planks, without devising a sturdier container for the pressing, or a complex press. Pressing between a counter top (or the floor) and a plank of wood, with weight on top (say, a 5 gallon bucket filled with water = 40 pounds) will work. But by using a wall-mounted lever arm, I could apply 65 pounds of weight using only a 1 gallon jug of water.

If more moisture is added to the tobacco, a crumble-cake can be made into a solid plank, from which a chunk can be crumbled off, rubbed out, then smoked. The purpose of crumble-cake is to prevent smaller bits (like Latakia) from sorting to the bottom of a container of tobacco during handling or shipping. The Brazil nut effect tends to leave you with a pile of fines at the bottom of a tobacco tin or pouch. (Brazil nut effect: within a container of objects with equal surface friction, agitation causes the larger objects to "float" to the top.) The higher the Latakia percentage, the greater the benefit of storing it as a crumble-cake.

In this demo, I did not add moisture to the tobacco blend (a Balkan Sobranie knockoff, with added Perique). With the tobacco in the lower half of the Ziploc, the bag was folded in half, with the top left unsealed. I pressed for 3 days under 65 pounds, spread over the area of the quart Ziploc folded in half. Surface area (4" x 7") is 28 in[sup]2[/sup], so the applied pressure was 2.3 psi. [psi = applied weight / surface area] The result is a soft crumble-cake that will not settle, if left alone, but readily rubs-out. I think this is adequate pressure to make a hard crumble-cake, provided that there is more moisture added to the blend, and it is pressed for a week or more.

I built this wall-mounted press as a cheese press (for merging curds into a solid cheese, like cheddar) a number of years ago. I've posted about it before, but it's been a long time.

It's simply a wood press arm on a wall-mounted pivot. The arm (poplar) has notches cut into the bottom at various distances from the wall, and its end extends beyond the kitchen counter surface, so that weights can be suspended from it. The suspended weights can be varied, and the press "piston" (just a pointed hunk of wood) distance from the wall can be varied. I determined the applied weight by placing a bathroom scale beneath the piston for each position and each weight jug.

The mounting board is anchored into the wall with 4 heavy anchor screws.

The pivot was purchased as a "Patio door roller" at Lowe's, for ~$7. (https://www.lowes.com/pd/National-2-01-in-Plastic-Sliding-Patio-Door-Roller/3034107) The wheel was replaced by my press arm, with a bronze bushing pressed into the pivot hole of the arm.

Since the press lives on the wall immediately above my kitchen counter, I added a keeper hook to make sure it doesn't bonk me in the head unexpectedly.

This modest amount of tobacco pressed to about 1/2" thick.

I could probably double the quantity of tobacco in the folded Ziploc without difficulty. What is noteworthy is that the 2.3 psi did not burst the open freezer Ziploc bag.

Bob

By placing a pipe blend into a (in this case, quart-size) freezer Ziploc bag, it can be pressed for general melding, or pressed into a crumble-cake between two planks, without devising a sturdier container for the pressing, or a complex press. Pressing between a counter top (or the floor) and a plank of wood, with weight on top (say, a 5 gallon bucket filled with water = 40 pounds) will work. But by using a wall-mounted lever arm, I could apply 65 pounds of weight using only a 1 gallon jug of water.

If more moisture is added to the tobacco, a crumble-cake can be made into a solid plank, from which a chunk can be crumbled off, rubbed out, then smoked. The purpose of crumble-cake is to prevent smaller bits (like Latakia) from sorting to the bottom of a container of tobacco during handling or shipping. The Brazil nut effect tends to leave you with a pile of fines at the bottom of a tobacco tin or pouch. (Brazil nut effect: within a container of objects with equal surface friction, agitation causes the larger objects to "float" to the top.) The higher the Latakia percentage, the greater the benefit of storing it as a crumble-cake.

In this demo, I did not add moisture to the tobacco blend (a Balkan Sobranie knockoff, with added Perique). With the tobacco in the lower half of the Ziploc, the bag was folded in half, with the top left unsealed. I pressed for 3 days under 65 pounds, spread over the area of the quart Ziploc folded in half. Surface area (4" x 7") is 28 in[sup]2[/sup], so the applied pressure was 2.3 psi. [psi = applied weight / surface area] The result is a soft crumble-cake that will not settle, if left alone, but readily rubs-out. I think this is adequate pressure to make a hard crumble-cake, provided that there is more moisture added to the blend, and it is pressed for a week or more.

I built this wall-mounted press as a cheese press (for merging curds into a solid cheese, like cheddar) a number of years ago. I've posted about it before, but it's been a long time.

It's simply a wood press arm on a wall-mounted pivot. The arm (poplar) has notches cut into the bottom at various distances from the wall, and its end extends beyond the kitchen counter surface, so that weights can be suspended from it. The suspended weights can be varied, and the press "piston" (just a pointed hunk of wood) distance from the wall can be varied. I determined the applied weight by placing a bathroom scale beneath the piston for each position and each weight jug.

The mounting board is anchored into the wall with 4 heavy anchor screws.

The pivot was purchased as a "Patio door roller" at Lowe's, for ~$7. (https://www.lowes.com/pd/National-2-01-in-Plastic-Sliding-Patio-Door-Roller/3034107) The wheel was replaced by my press arm, with a bronze bushing pressed into the pivot hole of the arm.

Since the press lives on the wall immediately above my kitchen counter, I added a keeper hook to make sure it doesn't bonk me in the head unexpectedly.

This modest amount of tobacco pressed to about 1/2" thick.

I could probably double the quantity of tobacco in the folded Ziploc without difficulty. What is noteworthy is that the 2.3 psi did not burst the open freezer Ziploc bag.

Bob