ShiniKoroshi

Active Member

What I am specifically referring to is chamber (bowl) design; taper vs. straight. All of my pipes have a tapered chamber and can give bite if smoked too hard. The pipe that I made has a straight walled chamber with a similar diameter and depth as the other pipes. However, I smoked that pipe hard, straight to the bottom, without the slightest hint of bite. Bottom of the chamber was completely dry in spite of 80-90% humidity. Repeated several times with blends I have that do bite and nothing. Then the bowl cracked on the inside which is pretty much the end of this experiment until I make another pipe (from briar this time). I did grab another pipe and verified the existence of bite with those particular blends under the current environmental conditions.

BTW, I usually smoke in high humidity and am used to keeping my powder (tobacco) dry and packing light.

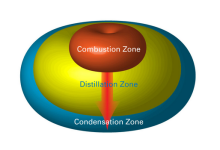

My theory is that the taper causes moisture and heat to concentrate on the small bit of tobacco near the bottom making the associated issues greater. But, I have very limited pipe smoking experience and would appreciate the thoughts of those who do on the matter.

Thanks!

BTW, I usually smoke in high humidity and am used to keeping my powder (tobacco) dry and packing light.

My theory is that the taper causes moisture and heat to concentrate on the small bit of tobacco near the bottom making the associated issues greater. But, I have very limited pipe smoking experience and would appreciate the thoughts of those who do on the matter.

Thanks!