I knew you were going to say that!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Search for freezer

- Thread starter marksctm

- Start date

- Status

- Not open for further replies.

leverhead

Well-Known Member

You don't have that there espn were you can read minds do ya?

I've heard he's psychotic, or something like that.

marksctm

Well-Known Member

I could use some help on wiring my kiln.

I drew a diagram of how I would like to set it up, but I need some to show me how to wire it.

Thanks Leverhead for helping to post the diagram.

Here's the diagram, the feed will be the pig tail with male plug, to the thermostat, to the gang box.

Thanks,

I drew a diagram of how I would like to set it up, but I need some to show me how to wire it.

Thanks Leverhead for helping to post the diagram.

Here's the diagram, the feed will be the pig tail with male plug, to the thermostat, to the gang box.

Thanks,

Last edited:

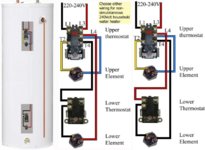

I attatched a wiring diagram for water heater thermostats. It looks like you have a lower thermostat. You only want to send 1 leg through the thermostat. Prefferably the hot leg. All the thermostat does is open the circuit when the desired temp is attained.

Ignore the top half of the wiring diagram just look at the lower thermostat. In your case pass the black wire through the thermostat, the neutral wire goes directly to the outlet.

do not put the neutral to the thermostat.

marksctm

Well-Known Member

Thanks DrBob she's wired and ready for operation.

My next question is, How do you load it, I've been laying out all my leaf nice and flat, but It's taking so long to do it this, I've only done 20 to 25 hands of tobacco out of close to 90 or more hands.

I know I can bring the hands up in case, then cut hands loose, put leaf in a neat pile, (but not unrolling every leaf and laying flat) then compress it flat and keep adding leaf, to a thickness of let's say, 4 or 5 inches thick and about the size of the shelves in the freezer.

But will the tobacco kiln properly in slabs of this size.

Or should it be filled loose, like when It's hung in the shed for color curing?

Thanks for any advice

My next question is, How do you load it, I've been laying out all my leaf nice and flat, but It's taking so long to do it this, I've only done 20 to 25 hands of tobacco out of close to 90 or more hands.

I know I can bring the hands up in case, then cut hands loose, put leaf in a neat pile, (but not unrolling every leaf and laying flat) then compress it flat and keep adding leaf, to a thickness of let's say, 4 or 5 inches thick and about the size of the shelves in the freezer.

But will the tobacco kiln properly in slabs of this size.

Or should it be filled loose, like when It's hung in the shed for color curing?

Thanks for any advice

Bullweviil

Member

wire it for 220 volts, when it burns the motor instant kiln.Yep, and if that nipple is plastic the conductive heat loss will be minor while it is a freezer. For me the down side is if it went into use as a freezer it would never see use as a kiln. -- John

marksctm

Well-Known Member

Thanks for your ingenious idea Bullweasel that has nothing to do with my question about my post. but from a post that was posted 65 posts ago.wire it for 220 volts, when it burns the motor instant kiln.

It's no wonder you only average 1 post a month since April when you joined.

Chris,

Using my Cozy Can as a kiln, I have been successfully kilning full, tied hands that hang from the top rail using a twist of wire. The heat prevents mold. The humidity easily penetrates the entire hand, and the leaf is similar beneath the hand tie, when compared to the free-hanging leaf. My conclusion is that ventilation between the leaves is not a requirement within a kiln. I think that you can load the leaf in any manner, stack or compress it in any configuration, and still end up with nicely kilned leaf.

Bob

Using my Cozy Can as a kiln, I have been successfully kilning full, tied hands that hang from the top rail using a twist of wire. The heat prevents mold. The humidity easily penetrates the entire hand, and the leaf is similar beneath the hand tie, when compared to the free-hanging leaf. My conclusion is that ventilation between the leaves is not a requirement within a kiln. I think that you can load the leaf in any manner, stack or compress it in any configuration, and still end up with nicely kilned leaf.

Bob

marksctm

Well-Known Member

Thank you Bob for answering my question.Chris,

My conclusion is that ventilation between the leaves is not a requirement within a kiln. I think that you can load the leaf in any manner, stack or compress it in any configuration, and still end up with nicely kilned leaf.

Bob

I've been running it for 3 weeks now with a small test load of some of my cigar tobacco, and after next week I'm wanting to get a full load in it, and I think I should be able to get all of 2012 grow in it.

I've switched out my old space heater fan with 2 of the 3 computer fans I picked up for 5 bucks each,

added my 1 inch riser with 1 inch ball valve on top,

and wired my thermostat, and 4 outlet gang box for 2 switched 110v outlets and 2 constant feed 110v outlets.

This is all new to me so I'm checking and rechecking everything trying to avoid any mishaps.

Here's a few pictures.

And Thanks again Bob.

marksctm

Well-Known Member

Looking good Chris. how's it feel to be this far along?

marksctm

Well-Known Member

Well sense I didn't even know about growing tobacco a year ago, or knew it was legal to grow, It feels like I've accomplished something.Looking good Chris. how's it feel to be this far along?

I started my first seeds a year ago last week, (February 14 2012 way to early) so 12 months with the right people and forum, and you can sure turn out a great batch of tobacco your first go at it.

And that's from sewing seeds, to planting, priming, color curing, rolling cigars, setting up a damn near carefree and safe kiln, that I would put up against anything when it comes to the quality of your finished tobacco leaf.

What a great collection of people from around the world to learn from.

So I guess the answer to your question is, I feel pretty damn good to be this far along.

Now, On to Chapter 2, 2013

Thanks Members, for all of your help.

leverhead

Well-Known Member

You made me stop and think about it, it is pretty cool.

That is a fine looking chamber Mark. The only problem I see is you may get some wall damage from the steam exiting the chimmeny condensing on the ceiling. An easy fix to that is another computer fan to blow the steam away from your ceiling.

Congratulations on a job well done.

Dr.Bob

Congratulations on a job well done.

Dr.Bob

FALaholic

Well-Known Member

Sry to bring this back from the dead.

But after reading your post...you owe me a new keyboard.

But after reading your post...you owe me a new keyboard.

AmaxB

Well-Known Member

Well sense I didn't even know about growing tobacco a year ago, or knew it was legal to grow, It feels like I've accomplished something.

I started my first seeds a year ago last week, (February 14 2012 way to early) so 12 months with the right people and forum, and you can sure turn out a great batch of tobacco your first go at it.

And that's from sewing seeds, to planting, priming, color curing, rolling cigars, setting up a damn near carefree and safe kiln, that I would put up against anything when it comes to the quality of your finished tobacco leaf.

What a great collection of people from around the world to learn from.

So I guess the answer to your question is, I feel pretty damn good to be this far along.

Now, On to Chapter 2, 2013

Thanks Members, for all of your help.

My feelings exactly... Well said.

FALaholic

Well-Known Member

Hit a freaking coil with the hole saw.

100% kiln now!

Sry to bring this back from the dead.

But after reading your post...you owe me a new keyboard.

DGBAMA

Well-Known Member

You guys are going to cause me to build a kiln. I wanted to keep things simple.

Harvested lugs today and my hanging method has me thinking perfect for kiln but maybe too dense for air drying.

Harvested lugs today and my hanging method has me thinking perfect for kiln but maybe too dense for air drying.

grgfinney

Well-Known Member

I just picked one up on Craigslist

- Status

- Not open for further replies.

Similar threads

- Replies

- 19

- Views

- 3K

-

About Us

This forum is dedicated to promoting the American tobacco farmer and tobacco home growers across the globe. Whether you grow by the acre, in your backyard, or in pots, you should find valuable and accurate information here.We discuss any variety of tobacco, as well as numerous approaches to growing, harvesting, curing, and finishing your crop. Our members will attempt to provide experience-based answers to your questions.

-

Buy raw tobacco from our Sponsor - WLT