You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

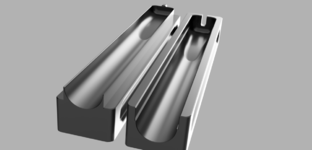

Making a mold: @Wolffman

- Thread starter Wolffman

- Start date

I’d expect material cost to be about $30. The cost of my engineering plastics has gone crazy the last 6 months. For example, I now pay $960 for a 1/2” x 4 x 8 sheet of Delrin. It used to be $600 a year ago.@Wolffman Could you guess at what the material cost would be for an 8 cigar mold for 8 inch cigars? I'm assuming 50 ring cigars (that's 50 / 64 of an inch in diameter). I'm guessing that milling something that big would be more practical than printing it.

BrotherJ

Well-Known Member

BrotherJ

Well-Known Member

P.S. I always imagined that a less-skilled cigar roller would just roll a smokeable cigar and it would end up being whatever ring size it happened to be. Getting the exact same amount of tobacco in every cigar would be something I would expect of someone who has rolled at least hundreds of cigars. A mold of a particular size might be less useful to a roller who just hasn't put in the time yet. Something @tullius said might work well here. What if you had a mold with seats for different ring sizes of cigar of the same profile? That way, you could stick your freshly-bound cigar into whichever seat fit best. That would be a great tool for the learner. I also had an idea that might antiquate the mold entirely: a three roller system with two free-spinners on bottom and one driven roller on top that could be moved into and out of position. Basically, the profile of the rollers would be a negative image of the profile you want from the cigar. Stick the freshly-bound cigar into the rollers, swing in the top one and spin it for a minute. This kind of system should be less sensitive to ring size. I'm sure someone somewhere has already tried something like that, but I've never seen it.

You have it correct, there is a right amount in the bunch when you're using a mold. But it's not hard at all to learn that line, especially when we have the Cuban vitola chartsThe right amount in the bunch is a fine line

If I jam a mold cavity too full, the mold will definitely compress the doll enough that it won't draw well. So, I roll the dolls so they *just* pop into the mold. No jamming but no loose gooses eitherI've never looked into whether or not a cigar mold could compress the cigar enough to effect the draw.

I'd recommend testing before and after putting in the mold. If the doll is too tight for your taste after coming out of the mold, you can always take it apart and rework it. Through some short trial and error experimentation, you'll get the right draw by feel aloneDid you test the draw with some unlit puffs before putting it in the mold?

@Wolffman, I bunch and bind dolls one evening, then press and leave them in the molds overnight (24 hrs.), turning them twice 1/3 of a turn within the first hour, and wrap them the next evening. That works for me with commercial polymer molds, and my schedule

Last edited:

For the record, those are the nicest tent peg stakes I've ever seenOff topic, but again sometimes I build stuff just because. Here’s a flagpole kit I did for our local Cub Scout pack a few years back. They were using a crappy PVC pole which was a real pain and a bit dangerous.

View attachment 43482View attachment 43483View attachment 43484View attachment 43485

@Wolffman Did you test the draw with some unlit puffs before putting it in the mold?

I've never looked into whether or not a cigar mold could compress the cigar enough to effect the draw.

Does anyone already know?

Yes, as has already been said the mold definitely affects the draw. Also, the amount of time left in the mold affects it as well. For example, I rolled a few 50’s that were in the mold for about an hour. They had a near perfect draw. But, they ended up being quite a bit larger than a 50 due to the expanding after coming out of the mold. I’ve got a few bunches in the molds now with less tobacco and pop into the mold with just a little resistance. I think that’s the key as Tullius stated.

I'm sure this against all cigar making etiquette, but I'm liking the look of the cigar being put back in the mold after wrapping. Especially with some of these wrappers that have heavy veins. Today, I'm making a few molds for this purpose. They are 50 ring molds that are oversized just a bit (0.030") so that they will fit into the mold easily and not damage the wrappers.

Compressing an overstuffed cigar in a mold will definitely cause an unacceptable draw. I have done this before, sadly, lol....@Wolffman Did you test the draw with some unlit puffs before putting it in the mold?

I've never looked into whether or not a cigar mold could compress the cigar enough to effect the draw.

Does anyone already know?

Just smoked a genuine Cuban Montecristo that I’ve had for a long time. It was my first Cuban ever. The cigar was put together really well and smoked good. But, I sure am liking some of these flavors I’m getting from rolling my own.

BrotherJ

Well-Known Member

Those are good looking cigars.

Impressive brother! May need to fire up my Ender 3 again soon. I tried using some files that are out there and had problems with the filament not sticking to the bed. Have an auto leveler wired up, but not hooked up… (if that makes sense). Considered a glass bed as well. 3D printing is a slippery slope! Lol

I will send you the file when you are ready.Impressive brother! May need to fire up my Ender 3 again soon. I tried using some files that are out there and had problems with the filament not sticking to the bed. Have an auto leveler wired up, but not hooked up… (if that makes sense). Considered a glass bed as well. 3D printing is a slippery slope! Lol

Similar threads

- Replies

- 30

- Views

- 17K

-

About Us

This forum is dedicated to promoting the American tobacco farmer and tobacco home growers across the globe. Whether you grow by the acre, in your backyard, or in pots, you should find valuable and accurate information here.We discuss any variety of tobacco, as well as numerous approaches to growing, harvesting, curing, and finishing your crop. Our members will attempt to provide experience-based answers to your questions.

-

Buy raw tobacco from our Sponsor - WLT