You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuck Cutter Blade Stencil

- Thread starter TigerTom

- Start date

- Status

- Not open for further replies.

stdly

Well-Known Member

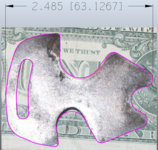

Grey on Black anyway I already did it with the dollar hope it's ok.

I've done this before, do not wish to see others struggle, and therefore offer the following in the same good spirit that @MarcL gave me good help some time ago:It is completely different shape also Bob's is sharp and yours is rusty.

Take a pic or scan it and I will draw it if you want. the pencil outline you did won't be close enough.

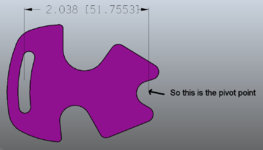

View attachment 34489

- @stdly's first blade scan doesn't work because the cutter Bob posted is markedly different from the MDB/K15, and poorly designed with a convex upper blade

- you can see with your eye that the pivot point of the first scan blade is way off center axis between the lobes. It should be centered

- take the dollar pic that @MarcL has provided and print it out, so that the dollar bill is the exact same size as a real dollar bill: this will take several tries to get it right

- take that paper and carefully cut out the shape of the cutter: this is now your template and it will work

- use an old handsaw blade as your material: chainsaw or handsaw files will work well, or a slow bench or pedestal grinder if you work slowly enough to not overheat the piece and take the hardness out of the steel

- to drill an initial local hole in the hardened blade, use an old dull drill bit and press it hard and spin way too fast for cutting steel: it will anneal the blade locally so that you can then drill it normally with a good bit

- do the rest of the work with the appropriate chainsaw or hand files

- Alternatively, you could anneal the entire piece, work it to shape, and then re-harden, but this is beyond the scope of most

Here it is all cleaned up with new lower blade made from a piece of an old handsaw. Decided I didn't need the small diameter cutter: had my fill of file work for today. Quick slapped it on this piece of wood and bunched ten edmundos to try it out. It works great! Had to tuck a piece of folded up foil up behind the star cutter to get it to cut flawlessly. There is something very final in the feel and sound of it working.

View attachment 29809View attachment 29810View attachment 29811View attachment 29812View attachment 29813

*Many thanks again to @MarcL for his kind help in finding and repairing this fine tool*

stdly

Well-Known Member

I've done this before, do not wish to see others struggle, and therefore offer the following in the same good spirit that @MarcL gave me good help some time ago:

@MarcL's dollar bill photo and advice should be added to the key forum threads: he knows what he's talking about, and it works

- @stdly's first blade scan doesn't work because the cutter Bob posted is markedly different from the MDB/K15, and poorly designed with a convex upper blade

- you can see with your eye that the pivot point of the first scan blade is way off center axis between the lobes. It should be centered

- take the dollar pic that @MarcL has provided and print it out, so that the dollar bill is the exact same size as a real dollar bill: this will take several tries to get it right

- take that paper and carefully cut out the shape of the cutter: this is now your template and it will work

- use an old handsaw blade as your material: chainsaw or handsaw files will work well, or a slow bench or pedestal grinder if you work slowly enough to not overheat the piece and take the hardness out of the steel

- to drill an initial local hole in the hardened blade, use an old dull drill bit and press it hard and spin way too fast for cutting steel: it will anneal the blade locally so that you can then drill it normally with a good bit

- do the rest of the work with the appropriate chainsaw or hand files

- Alternatively, you could anneal the entire piece, work it to shape, and then re-harden, but this is beyond the scope of most

Good info thanks!

I don`t own a cutter I am only copying what I see, not sure what a MD/K15 is?

The first blade was for Bob and I'm not sure it would fit any other cutter.

The second one was for TigerTom and again I am not sure it would fit any other cutter.

The third blade I did was for Marci from the dollar photo I haven't looked at the scans he made yet.

I am not sure if it's right either just copying the provided image and trying to help out, and again I am not sure if it would fit any other cutter.

Of course I noticed the slot was not centred which is easily moved but I don't even know the actual pivot point.

A masonry bit is carbide tipped or a solid carbide bit might be able to drill a hole in a hardened blade?

@Marci did you try the PDF I posted of your blade to see if it is close?

Older Dubrul tuck cutter. The "Star Cutter" was introduced later.

I can't speak to the design of the lower blade on my cutter, other than to say that it fits and seems to work. A star upper blade could be easily swapped onto my tuck cutter. It's a beautiful machine, and was a gift to me. Just trying to help.

Bob

stdly

Well-Known Member

Cool link like the prices. LOL

Older Dubrul tuck cutter. The "Star Cutter" was introduced later.

I can't speak to the design of the lower blade on my cutter, other than to say that it fits and seems to work. A star upper blade could be easily swapped onto the my tuck cutter. It's a beautiful machine, and was a gift to me. Just trying to help.

Bob

TigerTom

Well-Known Member

Good info thanks!

I don`t own a cutter I am only copying what I see, not sure what a MD/K15 is?

The first blade was for Bob and I'm not sure it would fit any other cutter.

The second one was for TigerTom and again I am not sure it would fit any other cutter.

The third blade I did was for Marci from the dollar photo I haven't looked at the scans he made yet.

I am not sure if it's right either just copying the provided image and trying to help out, and again I am not sure if it would fit any other cutter.

Of course I noticed the slot was not centred which is easily moved but I don't even know the actual pivot point.

A masonry bit is carbide tipped or a solid carbide bit might be able to drill a hole in a hardened blade?

@Marci did you try the PDF I posted of your blade to see if it is close?

The MDB/K15 mentioned is a model. I believe MDB is short for Miller DuBrul. While my cutter doesn't have any reference to Miller DuBrul on it, it is stamped K 15. Interestingly, after reprinting both of the designs, cutting them out, and measuring them to be sure they are to proper scale (using the reference measurements), neither Bob's nor Marc's cutter is quite right. On Bob's blade design, the track didn't line up with the thumb screw, and on Marc's design, the blades didn't properly line up with the bed of the cutter.

I was able to use both make a design that has a track that lines up with the screw and blades that properly line up with the bed. I'm not sure what I came up with will fit any other cutter, but I'll post my results anyway when finished.

Now I have to get to making it.

MarcL

Well-Known Member

That looks good....

@Marci did you try the PDF I posted of your blade to see if it is close?

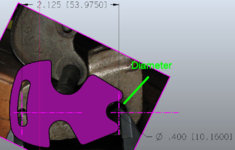

This is where the blade sits.

Slot/pivot measure from center. 54.3 mm

Maks's blade looks the same.

@TigerTom scored a star cutter. I suspect Bob's slot/pivot measure is greater then the star lower blade slot/pivot measure.

Yes it is. I can't say I remember where more pictures of that are but, I remember something. Maybe its that picture I remember... my tuck cutter. It's a beautiful machine , ..

Bob

stdly

Well-Known Member

That looks good.

This is where the blade sits.

Slot/pivot measure from center. 54.3 mm

Maks's blade looks the same.

@TigerTom scored a star cutter. I suspect Bob's slot/pivot measure is greater then the star lower blade slot/pivot measure.

Yes it is. I can't say I remember where more pictures of that are but, I remember something. Maybe its that picture I remember.

I understand the pivot point now thank you.

Are these cutters metric or inch were are they made?

These measurements would normally be a round number either in inches or metric when designing It's just easier that way when possible.

That means my cad drawing of your blade is no good as I have the pivot point at 51.755 from the centre of the pivot point to the centre of the slot.

Not sure if the pivot point is out or the slot because it overlays you dollar image very closely.

MarcL

Well-Known Member

Yeah. I can't say what they used then but, I can get an accurate measure. 54 mm is my guess.

MarcL

Well-Known Member

Your 51.755 measure is 54.0. The handles axle is 11.0 (O/D) and its cavity in the base is 11.5 I/D. The slot hole is 5.0 (I/D). The closes measure between them is 45.0 mm. The center slot to closer base cavity edge is 47.5 mm.

The original dimensions on the MDB/K15 were certainly in inches. @MarcL's lower cutter does show blade wear from sharpening over the years: just adjust the lower cutter to the bed profile, with a hook at the top end. The lower cutter edge should sit about 2mm above the bed for optimum performance.

stdly

Well-Known Member

Thanks!The original dimensions on the MDB/K15 were certainly in inches. @MarcL's lower cutter does show blade wear from sharpening over the years: just adjust the lower cutter to the bed profile, with a hook at the top end. The lower cutter edge should sit about 2mm above the bed for optimum performance.

If it`s inches the dimension would probably be 2.125 =53.97500 mm. That.s a guess it could be a copy of an earlier metric design.

Does anyone know the diameter of the pivot pin?

MarcL

Well-Known Member

The handles axle (pivot pin) is 11.0 (O/D) and its cavity in the base is 11.5 I/D.Thanks!

If it`s inches the dimension would probably be 2.125 =53.97500 mm. That.s a guess it could be a copy of an earlier metric design.

Does anyone know the diameter of the pivot pin?

View attachment 34514

just checked my K15: the least worn part of the handle/palm lever axle OD measures 0.450" right on with tested good stainless steel dial vernier caliper.

Don't see the need to go get a calibrated micrometer from the shop: close enough, for the purpose

hope that helps

Don't see the need to go get a calibrated micrometer from the shop: close enough, for the purpose

hope that helps

To my knowledge, there was no earlier metric design.it could be a copy of an earlier metric design

- Status

- Not open for further replies.

Similar threads

- Replies

- 6

- Views

- 2K

-

About Us

This forum is dedicated to promoting the American tobacco farmer and tobacco home growers across the globe. Whether you grow by the acre, in your backyard, or in pots, you should find valuable and accurate information here.We discuss any variety of tobacco, as well as numerous approaches to growing, harvesting, curing, and finishing your crop. Our members will attempt to provide experience-based answers to your questions.

-

Buy raw tobacco from our Sponsor - WLT